QUALITY CONTROL

At LEADMAN, the bedrock of our ethos resides in an unswerving commitment to quality control, a tenet we uphold with utmost gravitas and devoid of any compromise. This commitment permeates every facet of our operation, etching a narrative of uncompromising excellence.

A comprehensive and stalwart framework for inspection, measurement, examination, and testing converges seamlessly within the very fabric of our organizational workflows. A cornerstone in safeguarding our commitment to quality resides in the integration of an ERP system, a pivotal tool that orchestrates the entire spectrum of operational procedures, resource allocation, and standard adherence, thus fortifying the pillars upon which quality production stands.

Embracing the realm beyond the factory floor, our commitment extends to the customer experience and satisfaction, standing as cardinal pillars in the narrative of LEADMAN. This symphony of dedication harmonizes into a singular crescendo: the unwavering pursuit of quality that resonates within every facet of our operation.

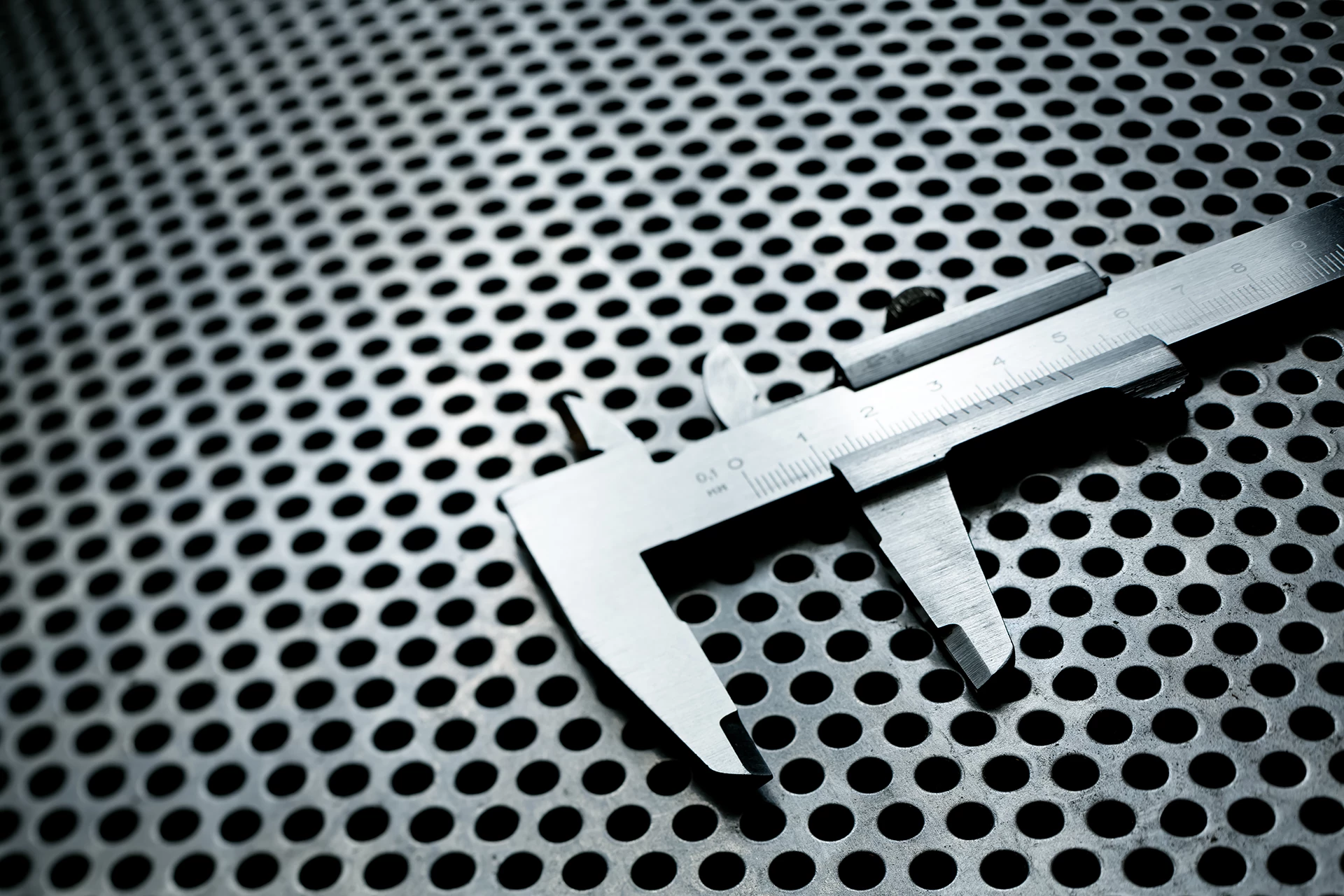

MEASUREMENT & CALIBRATION

In the realm of high precision engineering production, the accuracy and tolerances of each component along its manufacturing journey play a pivotal role in dictating the quality and efficacy of the entire process. Armed with a profound appreciation of this paramount significance, LEADMAN has consistently held a pioneering stance within the industry, dedicated to delivering these essential solutions to our valued clientele.

Married to our adept expertise is an arsenal of cutting-edge equipment, a combination that empowers us to offer an expansive array of solutions. These solutions encompass the precise measurement and calibration of tools and components spanning a spectrum of tolerances and distinct requisites, ensuring a realm of accuracy that echoes our commitment to excellence.